3D Printing & Blacksmithing

I have been 3D printing since 2017. 3D printing is an additive manufacturing process where you can make three dimensional REAL objects from a digital file. The process of making a 3D printed object is achieved by using a machine that interprets XYZ coordinates to lay down sequential layers of material until a digital object is created as a real object. Each layer is literally a thin cross-section of the digital object. By stacking the layers, you end up with a physical version of the digital object. 3D printing allows me to produce complex shapes and items at home that I may otherwise have to purchase or pay to have made. 3D printing is becoming increasingly accessible to more people as the printers are getting more reliable, printing materials get stronger and the number of pre-designed files that can be downloaded and printed grows exponentially. Here are a few of the ways I use 3D printing in my blacksmithing business.

Marketing

First & foremost, 3D printing is used as a marketing tool in my shop. Every box of forged goods that ships from my store will always have a small, 3D printed anvil in it. These are fun trinkets and blacksmiths love them.

I often hand out the 3D printed anvils and tiny hammers at blacksmithing events. They’re always a big hit and generally result in conversations about 3D printing and blacksmithing.

Rapid Prototyping

I’ve used 3D printing to rapid prototype several products and tools. My bottle opener blanks and coffee scoop handles are just two examples of products that were developed and tested as 3D printed objects first before being sent to laser cutting for production runs. I am constantly looking for ways to use 3D printing to speed up product development in my shop or to give me a physical, plastic item to hold in my hands and test before moving on to a steel version.

Tools & Gadgets in the shop

I use simple design software and 3D printing to make useful things for the blacksmith shop. A magnetic bracket for my induction forge water cooler and magnetic sharpie holders are just a couple of the useful things that I’ve designed and printed for use in my shop.

For Teaching & Instruction

Ryan Schweter designed this 3D printed hammer, you can buy the STL file and print it yourself by going to his Etsy Store I have used these 3D printed hammers and plasticine clay to teach forging techniques to new blacksmithing students. Clay and hot steel move in much the same way and by using the light weight plastic hammer, I’m able to show students quickly and effectively how the hammer shapes steel. Trying to teach with a steel hammer usually results in squished clay. The 3D printed hammer hits and leaves similar imprints as a heavy hammer and it can be used anywhere; it’s an amazing instructional tool.

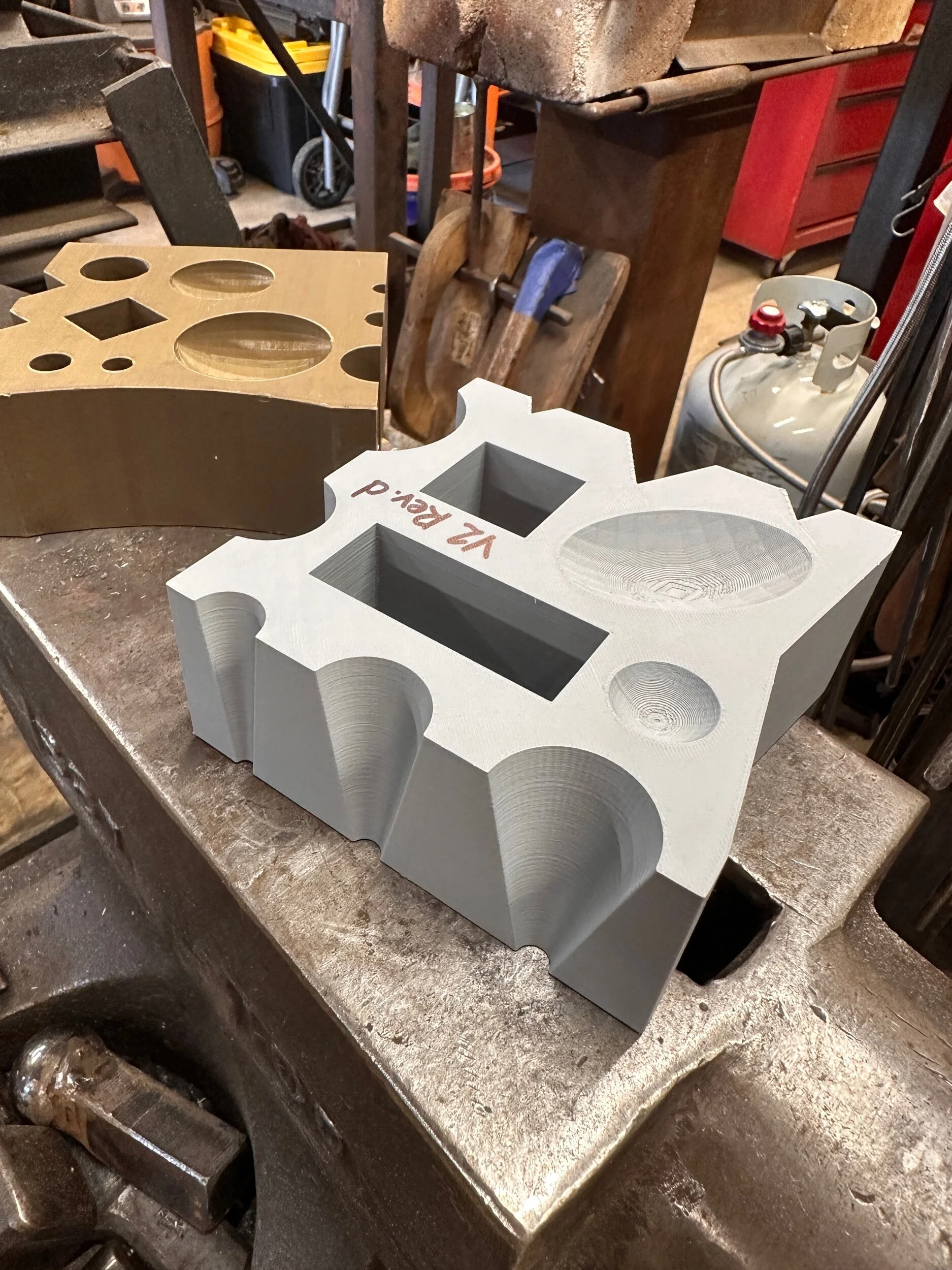

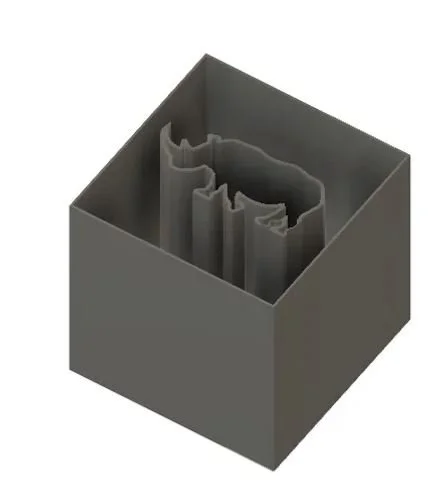

Canister Damascus

Several bladesmiths have begun using 3D printed “canisters” to form complex shapes with alternating steel alloys to create amazing patterns for blade work. I can take NO credit for this, the guys over at Kilroys workshop have worked with Master Bladesmith Steve Schwartzer to develop the process but I intend to put it to use in the future. To see more about what they’re doing and to learn more about how 3D printing and canister damascus work together check out their website https://www.3dcanister.com/

Photo credit: Kilroys Workshop

STL Repositories

Here are a few places to find and download ready-to-print STL files.

https://www.thingiverse.com/

https://cults3d.com/en

https://thangs.com/

https://www.myminifactory.com/

https://www.printables.com/model

https://pinshape.com/